Cold Seal Pressure Vessels

Our externally heated pressure device laboratory is presently equipped with three vessels employing a "cold-seal" design (see second figure). The cold-seals are designed for fast quenching applications (rapid freezing of high-temperature states), allowing a rapid, isobaric, gravitational removal of a run product from the temperature hot-spot by turning the furnace/vessel combination from a horizontal into a vertical orientation.

This design allows further to re-expose formerly quenched experiments (e.g. for synthetic fluid-inclusion entrapment) quickly into the hot spot under pressure (e.g. if immediate heat at P is required), or to investigate samples in a vertical orientation (e.g. for investigating segregation/gravitational gradients).

Lab impressions

-

Panoramic view of the cold-seal pressure vessel lab. -

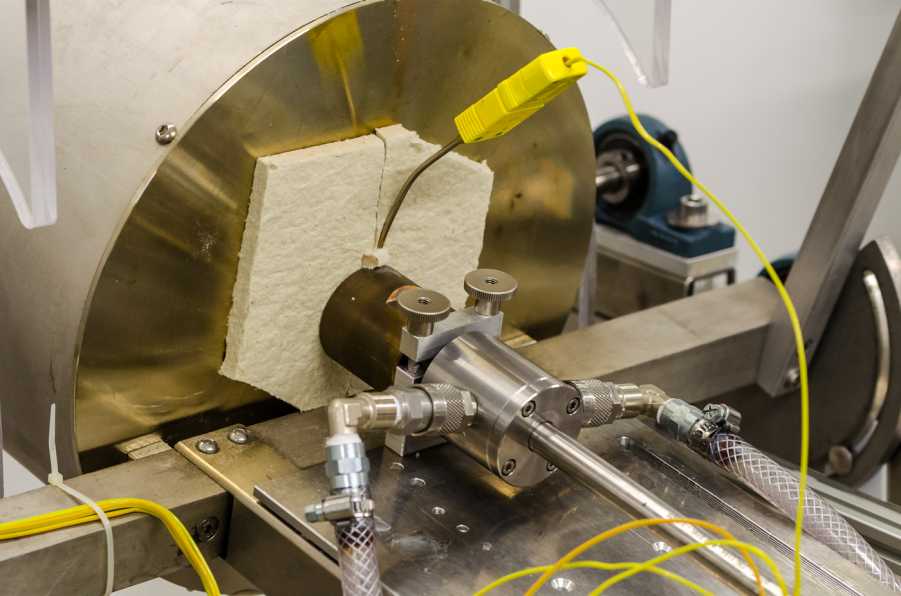

The water-cooled closure-nut connects the pressure vessel (hidden in the furncace) with the pressure lining (thin tube towards the lower right corner). Thus, the vessel is cold-sealed. The yellow connectors are part of the temperature control system. -

Analogue Heise pressure gauge. -

Temperature measurement and control. -

Top to bottom: 1) used pressure vessel and 2) new vessel, which is encapsuled in an Inconel tube to prevent oxidation. 3) worn-out vessel. -

Blown-up vessel. Note the horizontal fractures/cracks.

Short facts of the laboratory

- Vessel material: Molybdenum, - hafnuim, carbon-Alloy (MHC)

- Number of vessels: 3

- Pressure: up to 2 kbar

- Pressure medium: Ar or Ar-CH4

- Temperature up to 1100 °C

- Hot spot plateau: 2 cm at 1100 °C

- Thermal gradient at hotspot: < 7° at 1100 °C

- Recommended maximum capsule size: 20 x 5 mm

- External control of oxygen-fugacity (fO2) by using a gas mixture of Ar and CH4 as pressure transmitting medium

- Automatic logging of process parameters

Contact

Inst. für Geochemie und Petrologie

Clausiusstrasse 25

8092

Zürich

Switzerland